smcCable branch boxDue to the limitation of its unique internal design structure, it is impossible to use the more mature power inspection used in the past for substation and lines,grounding tool, Especially the electrical inspection work under full insulation and sealing has been threatening the safety of maintenance personnel.Analysis of the causes of some accidents in recent years shows the importance of strictly following the sequence of safety technical measures,If you operate in the previous method,Then in case the wrong line is stopped or a call comes in suddenly,When the device is powered on, it shows a fault or basic data error, etc.,The consequences will be extremely serious.

smcCable branch boxsealed electrical construction

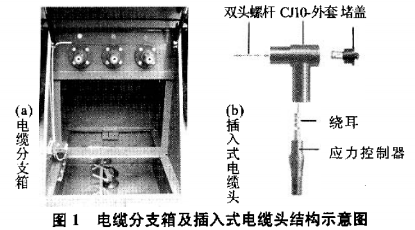

smcCable branch box(The structure is shown in the figure1)Plug-in cable made of silicone rubber

Composed of terminal head, double-way bushing, live indicator and stainless steel box,Fully enclosed design with compact structure,The cable is fully sealed, The cable sealing cap must be removed first, and the metal double-ended screw rod exposed by the blocking cover before the electric test can be performed.In the past, there was no electrical test before the cable head was removed.,And only by observing the charged display to judge whether the cable is live(regulationsL1not expressly stipulated in),If the electrified monitor breaks down and there are no other safety protection measures, It will endanger the safety of maintenance personnel.Although many domestic manufacturers aim atsmcCable branch box、Elbow-type grounding cable joints made of box-type transformers and ring network switchgears(see picture2)Can be used to complete final grounding work,However, the safety protection of the previous cable head removal work cannot be achieved, It is impossible to complete the complete technical measures.And this paper developssmcCable branch boxElectrical grounding tool(see picture3)solved the problem satisfactorily,can be completedsmcCable branch boxA series of safety technical measures that must be implemented when working in power outage,Ensure the personal safety of maintenance personnel.

smcCable branch boxHow to use the grounding tool for electrical testing

(1)Operating lever for removing the cable head(see picture3a) It can be used to remove cable sealing caps and blocking covers.The method of use is:a)Use the rotary adjustment handle to adjust the movable steel grip to the proper opening and closing,Hook firmly the cable cap opposite to the double-pass bushing of the branch box where the tested cable is located, and then pull it out,Expose the cable gland.b)The sleeve head is fitted with a sleeve matching the cable gland,Rotate the operating lever to loosen the blocking cap and pull out while twisting,After the plug cover is exposed to a certain position, adjust the movable steel grip by rotating the adjustment handle,Hook the edge of the plug to pull it out,Exposed branch box double-ended screw,That is, the demolition work is completed.

(2) Conventional acousto-optic test pens are used to test electricity on double-ended screws.

(3) Operating lever for installation of grounding wire(see picture3b)It is different from other Cantonese designs,Using a magnetic grounding device(Its ground wire is a three-phase group),It can prevent people from directly touching the branch box within the safe range of activities, The grounding wire can be directly installed without removing the metal double-ended screw rod, which is more convenient and safer.The method of use is:a)Ground first, followed by the conductor end.The grounding device part and the insulating operation part are magnetically attracted,Rotate joystick,The corresponding bayonet of the horizontal pin can be locked and drives the rotating grounding device.b)threaded connection(Its thread standard is based on the existing majoritysmcCable branch boxtwin screw2depending on size)Set insmcCable branch boxdouble-ended screw,Twist the insulator to tighten it,That is, the front end of the grounding device is connected.c)Push the insulating rod to make the spring contract and rotate an angle,Let the pin come out of the base notch, The thread at the rear end of the ground wire begins to be stressed.rotating insulating rod,Make the clip tightly contact with the threaded connection body and screw,That is, the rear end of the grounding device is firmly installed.dPull out the insulating rod and repeat the operation to connect all three phases,That is, the grounding wire is installed.

(4) Visible by usage,During the whole process, the maintenance personnel are prevented from directly touching the parts that may be charged,His personal safety was guaranteed.